Operating Efficiently

Conserving Water and Energy & Reducing Waste

Conserving Water

Water is a component of Fortune Brands Innovations’ manufacturing process, and we are focused on utilizing water in the most practical and efficient ways in our more water-intensive manufacturing processes.

Our facilities track water usage to allow FBIN to report on total water use. We rely on our operational and environmental, health, safety and security (EHSS) teams to identify water-related impacts to our manufacturing, primarily by finding ways to reduce the amount of water used, implement or maintain recycled water systems, or clean wastewater.

For example, our Fiberon plants utilize a closed- loop water system for minimal waste discharge, enabling Fiberon to reuse water, and saving nearly 3.5 billion gallons of water annually. We continue to look for ways to improve how we manage water in the manufacturing process.

Using the World Resource Institute’s Aqueduct Water Risk Atlas, we have identified the level of water-stress for our FBIN sites; for facilities in areas of higher water scarcity risk, we will evaluate further opportunities to conserve water usage and help mitigate the risk of water shortages and higher water cost.

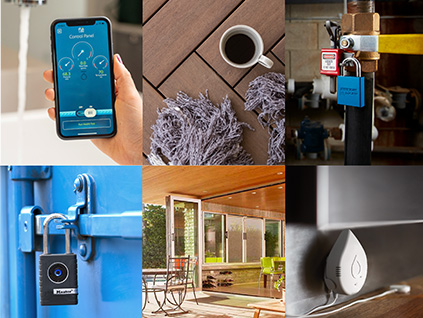

Additionally, innovative offerings like the Moen Smart Water Network exemplify how we are leading the charge into a new era of monumental change in how people encounter water every day.

Conserving Energy

The majority of our locations have switched to energy-efficient lighting, and we routinely check and repair our equipment to ensure it is running efficiently. We also invest in new equipment that is more energy efficient. While we have already taken many actions to run more energy-efficient operations, we are on the lookout for more opportunities to conserve energy.

Reducing Waste

Reducing waste streams is better for the environment, and can also help us save money. All Fortune Brands Innovations facilities have a commitment to manage waste streams in support of our Environmental, Heatlh & Safety Principles. In 2024, 10 of our manufacturing and distribution center sites achieved a recycling rate of 75% or better.

Our associates look for innovative opportunities to reduce our contribution to the waste stream. Their innovation and stewardship help us reduce our environmental impact and strengthen FBIN with additional value creation.